This is how we work

Production takes place in our own factory in Alby, where sales representatives and designers develop the solutions together with you.

Analysis and advice

A good needs analysis asks the important questions early on.

This is to find the right solution and the best conditions for an efficient project. We encourage everyone to think carefully about their needs. Depending on the degree of complexity, we help with analysis and advice.

Once we have taken note of your requirements and needs, we suggest solutions and highlight critical factors that can affect the end result. We also carry out tests, for example regarding the choice of materials and function. Our experience and expertise will help you find the right protection at the right time.

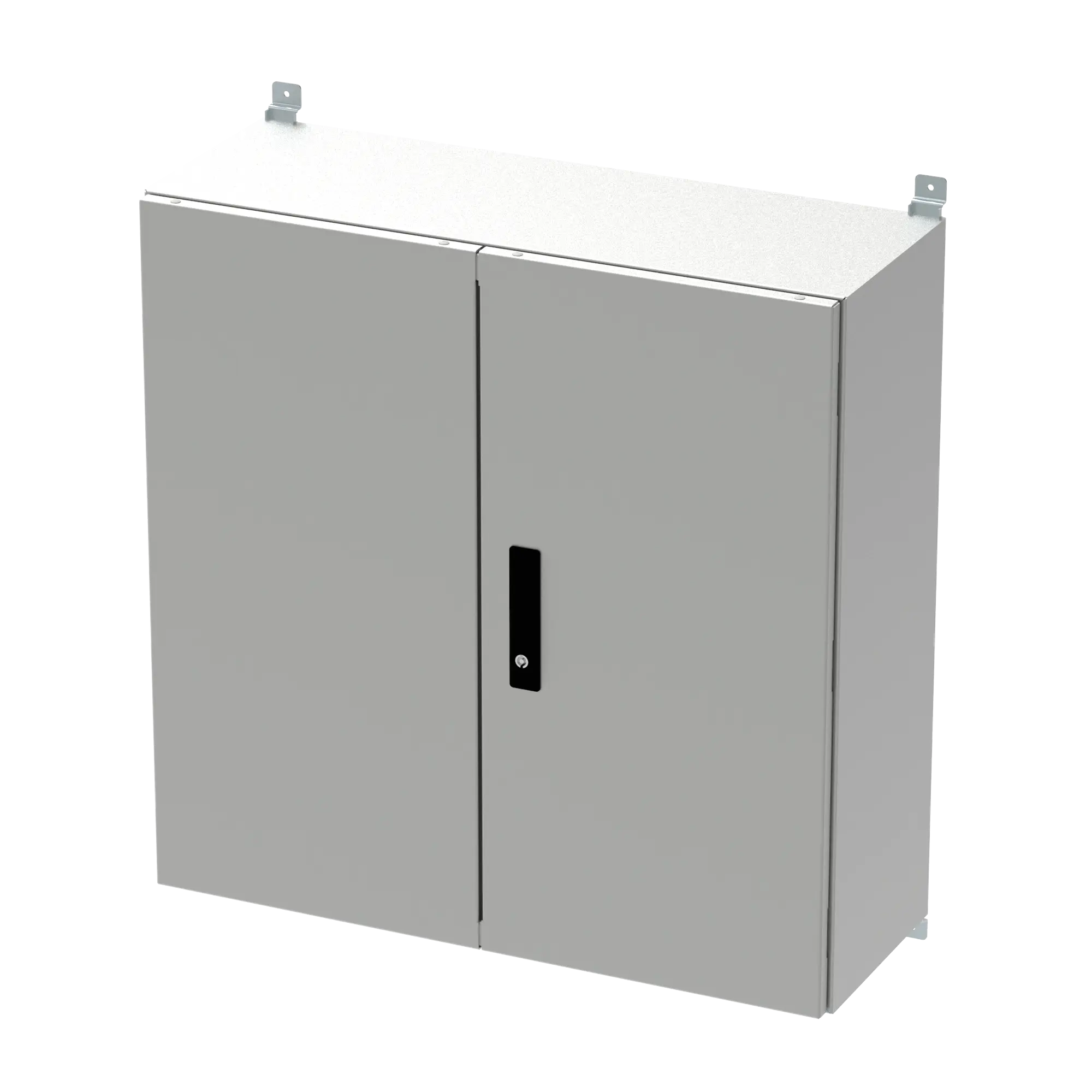

Design and build

We develop models and sketches together with you, so that all needs are taken into account.

A well-executed preparatory work saves both time and money. Our designers have extensive experience and broad expertise in electricity, heating, cooling, tightness, corrosion requirements and sheet metal processing. Get help from us for quick advice or support for longer periods.

A well-executed feasibility study provides better and more economically sustainable results, especially for advanced solutions. We collect information about conditions and needs, carry out tests and build prototypes. After that, we will work with you to draw up a plan for production and delivery.

Production and delivery

Production takes place in our own factory.

We are equipped with high-tech machines and experienced employees. The flow is adapted to be able to quickly handle changes and rests on a responsive collaboration with you.

Follow-up and evaluation

Follow-up and evaluation are important in order to identify areas for improvement, both functionally and financially.

We take our work seriously, deliver with pride and strive to develop together with everyone we work with. It builds strong relationships and profitable businesses.

Customization

About us